Measuring and marking:

Laying out:

For completing the above work the shape of the object should be carefully checked and it should be divided into simple geometrical solids. Then the solid obtained by above division can be developed separately and then sheet is cut. These separate pieces are joined together. It will give the required object.

Basic concept of development of surfaces is explained as, let us take a cylinder which is wrapped round its curved surface by a piece of paper. If wrapper is opened and spread on the sheet it forms a rectangle. The surface is the development of complete circular surface.

Cutting and shearing:

The word cutting is normally used when the sheet metal is cut by means of chisel and a hammer manually. The term shearing stands for cutting of sheet metal by two parallel cutting edges moving in opposite direction. This can be done either manually by using head shear or snips or by means of machines called shears. The operation is then known as machine shearing or mechanical shearing.

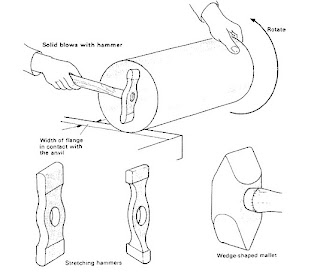

Hand forming:

The term metal forming stands for shaping or bending of sheet metal in three dimensions in order to give it desired shape and size of the final product. For this, the metal is either required to be stretched or spunk in all directions or may need a combination of both.

Nibbling:

It is a process of continuous cutting along a contour, which may be a straight line or an irregular profile. The machines used int his operations are known as nibblers, which are portable type shearing machines.

Circle cutting:

It is the operation of circular cutting blanks or curved contours with the help of a circle cutting machine. It is also a continuous cutting operation.

Piercing and blanking:

Piercing is basically a hole punching operation while blanking is an operation of cutting out a blank. In both the cases blanks will be produced, but in the former case obtaining a blank is not the objective. It is the hole of a desired size which is the objective and the blank produced may not be used further. In the latter operation the production of a blank of the desired size is the main objective, which is a useful part for further processing.

Edge forming and wiring:

The edges of sheet metal products are formed to ensure safety of hands while handling these products and to avoid stiffness to the products in order that they will retain their shape during handling i.e. will not get buckled or compressed by simple hand or finger pressure during handling.

Joint making:

Several means are used for joining sheet metal parts together or securing them to other metallic or non-metallic bodies. In case of very large size parts, especially when they are to be fastened to other metallic or large non-metallic bodies, screwed fastening can be used. Sheet metal parts can also be joined by riveting, welding, brazing and adhesives. Self tapping screws are more popular screwed fasteners in sheet metal work. However, still the most commonly used methods are joining the sheet metal parts by means of folded joints or self securing joints, followed by soldering and adhesive joining.

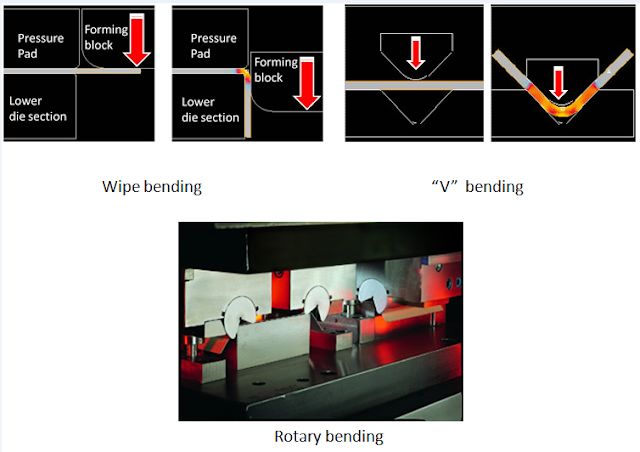

Bending:

Sheet metal is required to be bent at different angles to shape it into the required form. The bending operation involves stretching of metal on the other surface an comprising it on the inner surface along a neutral line, which remains unchanged in length. Sheet metal can be bent by hammering over a base by hand or by means of bending or rolling machines.

Drawing:

Thin walled hollow shapes are produced in sheet metal through the drawing operation. The operation is carried out with the help of die and punch on a suitable press. If the drawn length of the component is less than its width or diameter it is called box drawing or shallow drawing. When the drawn length is more than the width, the operation is known as deep drawing.

SAFETY WHILE WORKING IN SHEET METAL SHOP

a. Since in sheet metal work we use sharp tools and sharp cutting edges and precise hammer work is also involved so very skilled labor is used.b. Avoid using any tools whose edges are blunt or out of order.

c. For cutting sheets appropriate cutting tools or machines must be selected based on the thickness of the material to be cut.

d. Extra allowance must be provided in the sheets while cutting. So that the finished product is of correct size and finish.

I read this blog, it is a good looking article. Thanks for sharing this blog and article. We also manufacturers of Roofing Sheet Making Machines Roofing Sheet Making Machines

ReplyDeleteNice post and its very useful for us. We also the manufactures of Roofing Sheet Making Machine Manufacturers Roofing Sheet Making Machine Manufacturers

ReplyDeleteReally Nice Blog Post. Thanks for sharing this interesting post about packers and movers.

ReplyDeletesheet metal manufacturers Faridabad

Polycarbonate multiwall sheets are very light in weight and the multiple layering also makes them strong and virtually unbreakable.

ReplyDeletePolycarbonate Roofing Materials|Polycarbonate Roof

This comment has been removed by the author.

ReplyDeleteWow wonderful post good imfromation. Thanku share this post.

ReplyDeletesheet metal manufacturing companies gurgaon

Thanks for the blog...such nice information

ReplyDeleteMetal roofing sheet

Wow you are wanderfull and usefull post .Good ang High quality in Low cost sheet metal solutions provider in Delhi,Faridabad,Noida and Gurgaon for sheet metal services.

ReplyDeletesheet metal manufacturing companies noida

Nice Blog.

ReplyDeleteRoofing Sheets in Chennai

Roofing Contractors in Chennai

Industrial Roofing Sheets in Chennai

Hotel Roofing in Chennai

Roofing Fabrication in Chennai

Commercial Roofing Contractors in Chennai

Metal Roofing Sheets in Chennai

Nice Blog..

ReplyDeleteSheetmetal Manufacturers in Tamil Nadu

Sheetmetal Product Manufacturers in Andhra Pradesh

Sheetmetal Product Manufacturers in Chennai

Sheetmetal Product Manufacturers in Bangalore

Sheetmetal Product Manufacturers in Pune

Sheetmetal Product Manufacturers in Coimbatore

Great Article… I love to read your articles because your writing style is too good, its is very very helpful for all of us and I never get bored while reading your article because, they are becomes a more and more interesting from the starting lines until the end.

ReplyDeletePoly Carbonate Roofing in Chennai

Good ang High quality in Low cost sheet metal solutions provider in all over india for sheet metal services.

ReplyDeleteSteel Suppliers in Chennai

This comment has been removed by the author.

ReplyDeleteshipbuilding applications development services

ReplyDeleteI often search blog like this, which has content with images, we can also say that image description. Keep going.

ReplyDeleteThank you!

Special metal cutting bandsaw machines

This article is very informative and intersting,Thanks for sharing such an informative article with us.

ReplyDeletekeep updating.....

Steel Sheet Bending

Hi, Nice post.

ReplyDeleteThanks for sharing great post. Keep continue.

This is really very helpful information. I appreciate it, thanks for share it. Get more details about Shearing Machine Manufacturer

ReplyDeleteThis is such a beneficial information. I was searching for Shearing Machine Manufacturer. Thanks for sharing this.

ReplyDeleteNice article...Sir.

ReplyDeleteA detailed information about Sheet Metal Operations of Punching, Blanking,Deep drawing and Bending operation was presented here https://www.google.com/amp/s/mechanicalstudents.com/sheet-metal-operations-punching-blanking-deep-drawing-bending-applications/

Nice article...Sir.

ReplyDeleteA detailed information about Sheet Metal Operations of Punching, Blanking,Deep drawing and Bending operation was presented here https://www.google.com/amp/s/mechanicalstudents.com/sheet-metal-operations-punching-blanking-deep-drawing-bending-applications/

We are Precision Sheet Metal Components Manufacturers Company in India

ReplyDeleteWe'll work with your team to understand your goals and provide solutions to match. A DataIT Solutions is proud to deliver superior customer service through our dedicated internal team.

ReplyDeleteSheet Metal Contractor Website Design

Such a nice writing. The style you have narrated is simple beautiful and well authored. The quality of writing can be seen from the beginning until the end.

ReplyDeletePlasma Controls

This post was very well written, and it also contains a lot of useful facts. I appreciated your professional manner of writing the post. Thanks, you have made it very easy for me to understand.

ReplyDeletedeep drawing steel

Everything is very open with a precise description of the issues.

ReplyDeleteIt was truly informative. Your website is very

helpful. Many thanks for sharing!

microsoft office 2007 keys

IDM

Easeus Data Recovery

Windows 7 activator

4k video downloader

Microsoft office 365

Windows 10 activator

xforce keygen

ReplyDeleteI was searching about these tools and finally found your blog amazing list thanks admin.

Windows 7 activator

Windows 10 activator

4k Video Downloader

Windows 10 Product Keys

Office 365 Product Keys

Office 2016 Product Keys

Electric shears from TRUMPF for the cutting of mild steel TRUMPF provides tinsmiths, plumbers, electricians, heating and ventilation specialists, as well as container or elevator constructors with numerous shears which are optimally adapted to their intended purpose. A chip-free slitting process Using the sheet metal cutters, you can cut without burrs and thermal influences.

ReplyDeleteThanks for sharing with us.

ReplyDeleteCustom Software Development Company in USA

nice poststeel fabrication companies in bangalore

ReplyDeleteGreat information on blog. keep posting.

ReplyDeletewe sell cutting machine in Ambala.

The use of UN certified bags! can improve a company's reputation, showcasing their commitment to safety and compliance. Clients are more likely to trust businesses that prioritize responsible handling of hazardous materials.

ReplyDeleteGreat article! Your detailed explanation of various sheet metal operations is very informative and helpful for understanding the processes involved in manufacturing. It would be great if you could also include some insights on modern tools like the sheet metal folding machine, which plays a crucial role in precision folding and bending operations. Thanks for sharing such valuable content!

ReplyDelete"Great insights! I completely agree that the right tools make all the difference. Using quality sheet metal cutters not only ensures precision but also improves efficiency. Whether you're working on DIY projects or professional tasks, investing in durable cutters is a game-changer!"

ReplyDeleteGreat post! At HLH Prototypes Co. Ltd., we understand the importance of precision in sheet metal operations. Whether it’s laser cutting, bending, or stamping, these processes are essential for producing high-quality prototypes and parts. We use advanced techniques to ensure accuracy and efficiency, offering our clients fast turnarounds and cost-effective solutions. Thanks for sharing such a detailed overview of these crucial operations!

ReplyDeleteLeading custom metal stamping company, we specialize in creating and manufacturing premium stamped metal components for a range of sectors.

ReplyDeleteGreat insights on scheme x This post clearly explains the importance of BIS compliance for manufacturers and importers. Understanding helps businesses maintain product quality and meet Indian standards effectively. Thanks for sharing such valuable information — very helpful for companies seeking certification guidance!

ReplyDeleteBIS Certification for Foreign Manufacturers – BIS FMCS

ReplyDeleteGreat insights shared here! BIS Certification for Foreign Manufacturers is becoming increasingly important for global companies planning to enter the Indian market. Through the BIS FMCS scheme, foreign manufacturers can ensure their products meet India’s mandatory quality and safety standards. This not only supports smooth import clearance but also helps build trust with Indian buyers. Highlighting the FMCS process and compliance requirements is very useful for overseas businesses looking to expand into India. Thanks for providing such helpful information—it definitely adds value for manufacturers aiming for long-term success in the Indian market.

Great explanation of various sheet metal operations! The visuals and breakdown make it easy to understand how each process shapes the final part. Leading Sheet Metal Components Manufacturers rely on these operations to ensure precision and consistency. Thanks for sharing this helpful content!

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteInnovation in the steel manufacturing industry is driving modern green construction Green Building. Advanced fabrication methods and prefabricated steel structures improve durability, reduce waste, and enhance energy efficiency. Sustainable steel solutions support faster project completion while maintaining structural strength. With eco-friendly materials and smart engineering, industrial buildings are becoming more cost-effective and environmentally responsible. Continuous innovation ensures stronger, safer, and more sustainable infrastructure for the future.

ReplyDelete