Forge welding:

This welding is done by the black-smiths. In this two similar metal pieces are heated upto the plastic stage in the furnace. Then it is hammered so that a homogenous mixture is formed at the joint. The surface to be joined should be cleaned and made free from any foreign particle this is done by brushing.

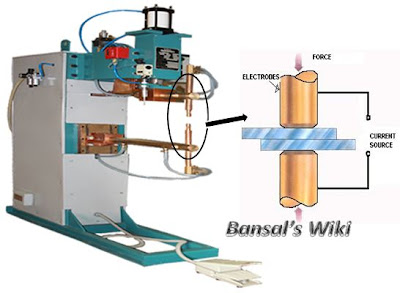

Spot welding:

It is a method for making lap welds for sheets upto 13mm thickness. It consists of a transformer having primary and secondary windings. This welding consists two arms, first is movable arm and the other is fixed arm, both these arms are connected by secondary coil of the transformer. In this process, we take two sheets to be joined and it is placed the manner between the two arms, then a supply of high amperage and low voltage is supplied between the two sheets. The pressure is also exerted by the fixed and the movable arm. As a result the temperature of the adjoining surfaces is brought upto the melting point and it is joined due to external pressure. This principle is fixed in a spot welding machine in which the pressure is applied by lever fixed in the lower portion of the machine that is operated by foot.Seam welding:

The principle of seam welding is same as that of a spot welding, only difference is that the tips of the spot welding is replaced by rotating wheels. As a result, it is a continuous welding process whereas spot welding is intermittent in nature. In this process the two material strip is fed between the two rotating wheels that act as an electrode, a supply of high amperage and low voltage is maintained between the electrodes. Before welding the surface to be joined is cleaned by brush. It is very fast welding process, and the strength of joint obtained by seam welding is more.Thermit welding:

It is used on those places where there is no availability of electric supply or gas. It is a compact unit and can be moved easily upto the site. It consist of a conical shape vessel with a brick lining inside. Mixture of powdered aluminium and iron oxide is placed inside the vessel. This mixture is heated by the furnace upto molten stage, due to reaction the aluminium is converted in Aluminium oxide. The molten metal is allowed to fill in the cavity. Then the mould is allowed to solidify. It is also economical and fast process. Welding joint made by this process is also very stronger.

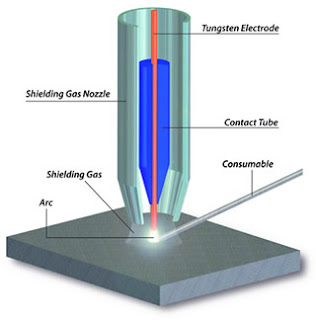

Tungsten inert arc (TIG) welding:

It is a process in which electrode is held in a electrode holder in such a way that it holds the electrode. It also ensures supply of inert gas around the electrode that created an inert atmosphere around the arc. Cooling during welding is done by the electrode holder by supply of water or air. It is a process which produces both continuous or intermittent weld. Filler metal is not used in this process. It is used to join Al-alloys, Cu-alloys, Mg-alloys, nickel-alloys.

Metal inert gas(MIG) welding:

In this case electrode is in form of continuous wire that is fed into the arc, speed of the wire is controlled by an electric motor. The electrode holder feeds the wire i.e. electrode and it also ensure supply of inert gas to the arc that creates an atmosphere which provides an inert atmosphere for the arc. This is used for welding low alloys steels, aluminium alloy, magnesium alloy, copper alloys etc.

Carbon dioxide MIG welding:

It is similar to metal inert gas welding. Carbon dioxide gas is used as an inert gas during this welding process as a shield. The electrode is coated and it is fed similar to MIG. It is a fast welding method, initial preparation before welding is not required. The joint produced by this method is very strong.Plasma arc welding:

In this process a mixture of gases such as argon, hydrogen and helium is passed through an electric arc due to heat it is ionised. This is called to be as plasma and it is passed through welding torch. The piece of metal to be joined is heated through this and tungsten electrode is used as filler material with water as a cooling agent. This can be used for cutting.

This is very informative !! You are a very experienced blog writer.Forge welding is one of the most fundamental techniques of black smithing,but one of the trickiest to master. It requires speed, precision, and practice.Keep on update your blog, Also I’ve distributed your website in my public networks!

ReplyDeleteLogos Weld is one of the top welding electrodes machine manufacturers,suppliers & Exporters in India.Get world class welding electrode manufacturing machineries at affordable prices.

It's really helpful to see these diagrams of welding. How difficult was it to learn all of these techniques for welding? I bet it would take so much practice! I had a metals class in school, and we learned to weld an even line on these metal plates. It was so hard!

ReplyDeleteCeline | http://www.bigbluewelding.com/services.html

Nice blog posted here. If anyone looking for wire manufacturer in india then contact Precision Drawell. Thanks for posting.

ReplyDeleteGreat blog. Thanks for sharing information. Butt-Weld Fittings We are the prominent supplier of excellent quality Butt Weld Fittings that are available in various finish and standards

ReplyDeleteChaga mushroom dinner might have been taught a lot of globally by means of Euro contributor Alexandr Solzhenitsyn michael’s narrative ‘Cancer Ward’ exactly where the large person could alleviated linked with types of cancer among help from this specific coffee. Chaga Mushroom click this link now

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteIt is to some degree fabulous, but look at the guidance at this treat. all about mig welder

ReplyDeleteCool stuff you have got and you keep update all of us. bezplatno

ReplyDeleteGreat information about welding techniques. keep posting good blogs.

ReplyDeletewe manufacture airless spray pump in ludhiana.