Drawing:

Drawing is the process in which a red hot metal piece is beaten up by a hammer. The thickness or diameter is decreased but length increases. The hammering is done by placing the hot piece on the anvil. First the rod is heated to the plastic stage in a furnace up to the desired length. The piece is kept on the horn as well face of the anvil or on bottom part of fuller followed by hammering with the pean of the hammer. If the shape is round then initially it is converted into square shape by the face of the hammer and length is increased. Then it is converted into octagonal shape and hammering is continued till final shape is achieved.

Upsetting:

It is the process in which the diameter of the hot work piece is increased and the length is reduced. Hot metal piece is placed on the anvil in vertical position. It is struck with a hand hammer. The hot work piece is held in a tong. Sometimes during upsetting, bending occurs on the job. In such cases first the job should be straightened and then upsetting should be continued.

Punching:

Punching is the process in which a rough hole is made into the hot work piece. The job is heated to a desired temperature and then it is placed on the anvil. Punch is placed on the hot metal piece. With the help of sledge hammer, the punch is forced to pierce the metal upto half of the metal thickness. Then the punching is done from the second side by inverting the work piece. A rough hole is produced.

Drifting:

It is a process of finishing and enlarging the hole. The process is similar to punching. To continue punching without using a die is called to be as drifting but in this case a tool known as drift is used.

Swaging:

Swaging is a process used to form or finish different shapes such as circular, hexagonal and square etc. The hot piece is held between the upper and lower part of the swages. With the help of a hammer blows are given to the upper part of the swage.

Fullering:

Fullering process is done on an anvil. Lower part of fuller set is kept in the hole of the anvil. Hot work piece is placed in the groove of the lower fuller. Upper fuller is placed on the job and hammering is done on the upper portion. Fullering is done for drawing and grooving.

Bending:

The process of giving desired angles or curvature to hot piece is known as bending. The process is done on the edge of the anvil or on chipping block. Circular shapes, eye bolts hooks or any other type of bent shape can be prepared with this operation. The hammering is done on hot work piece with a hand hammer. Hot work piece is held in a tong.

Forge welding:

The process of joining two metal pieces by heating and hammering is known as forge welding. The metal pieces to be welded are cleaned and heated in a furnace up to the welding temperature. Then both pieces are picked from the furnace with the help of tongs. Work pieces are placed on each other and hammering is done on them. And both the pieces get welded. The following factors must be considered while welding:

• Metal pieces should be clean and free from any scale.

• Pieces should be heated upto proper temperature.

Sometimes flux is also added while welding process. There are three types of welding joint in common use:

a. BUTT WELD:

When the two ends of work piece are joined in longitudinal direction, the joint is butt weld joint. This joint is difficult to form as hammering cannot be easily in weld direction.

b. LAP WELD:

This is also known as scarf joint. The end of the work pieces to be joined are made to overlap each other. Pressure can be applied easily with a hammer.

c. V-WELD:

It is a very strong joint. It is made where work piece thickness is more.

Cutting:

It is done by hot and cold chisels. It is an operation done before the finishing operation for removing the extra stock of material from the work piece. Cutting is done at the edge of the anvil or on chipping block provided on the anvil.

HOT WORKING PROCESSES

The processes which are done above the re-crystallization temperature are known as Hot working processes.

Advantages

1. Gain structure is refined.2. Physical properties are improved.

3. Porosity is minimized.

4. Less force is required for deformation.

Disadvantages

1. Rapid scale formation.2. Close tolerances cannot be obtained.

Main Hot working processes are:

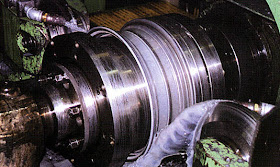

Rolling:

Rolling is the process of reducing the sectional area of metals. The hot metal is passed through two rolls running in opposite direction at some suitable speed. The space between the rolls is kept in accordance with the desired thickness. A number of articles like angles, T-sections, sheets, round bars etc. are produced by rolling.

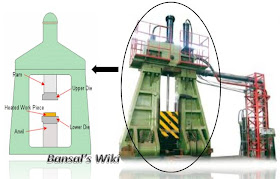

Drop forging:

Drop forging is a forging process which is done on a drop hammer, on drop hammer steel dies are used. The die is generally made in two halves. Upper part of the die is attached to the tup of the hammer and the lower part is placed on the bed. While working on it, the upper part of the die is raised to a height, with the help of the rope, chain or rollers. The red hot metal piece is placed on the lower part of die and the upper part is allowed to fall freely on it. A heavy blow is caused due to the falling weight of the tup The forging is done in this way. Main factors to be considered in a drop forging process are:

a. Falling weight.

b. Height of falling weight.

Press forging:

In this case metal is heated upto plastic stage then metal is pressed through die slowly by the press. Pressure that are used for light work is mechanical press and for heavy work hydraulic presses are used. By this method complicated type of shapes can be forged with better accuracy. In this type of forging life of the press machine as well die is more as compared to other forging methods.

Machine forging:

In this portion metal i.e. rod is heated up to the plastic stage then it is held between the two grooved dies. Pressure is applied along the axis on the rod as a result a localized upsetting i.e. increasing the diameter of the rod takes place. The cavity in the dies is designed so that the complete deformation takes place gradually inside the die.

Spinning:

Spinning in the process in which the sheet metal is heated to forging temperature and then forming into desired shape by rotating it on lathe. Cylindrical shapes can be formed by spinning process. Hot spinning is done when cold spinning is impossible due to thick jobs. A blunt tool is used to press the rotating work piece.

Hot extrusion:

Hot extrusion is the process of forcing a hot metal piece through small openings. Desired shape can be achieved by using suitable dies. Proper lubrication is necessary at the die hole.

Hot drawing:

The process of producing cup shaped jobs from sheet metal is hot drawing. The hot sheet piece is pressed by punch into the die to form desired shape. Soft materials are used for drawing .

COLD WORKING PROCESSES

The process which are done on the metals by keeping temperature below re-crystallization temperature. The force required for these processes is high as compared to hot working process. Cold working processes are also applied for soft materials otherwise the work piece will crack. In cold working processes strength and hardness is increased but grain structure is distorted.ANNEALING

The process of softening the materials is known as annealing. The brittleness is removed and the material became ductile. This helps in easy working of metals at low temperature. It is done to remove the internal strains in the material that are caused while cold working operations. Annealing increases ductility and decreases hardness. Metals to be annealed are heated up to certain temperature known as annealing temperature and then cooled slowly. The cooling is done either in ash or sand.

HARDENING

The process of heating the metal upto certain temperature and then quenching the hot metal in to water or oil is known as hardening. The ductility of the metal is eliminated and the metal become hard. Hardened components are used where the chances of wear or breakage are more. Hardness of metal depends upon proper quenching of the steel after heating. Another factor that affects the hardness is known as percentage if carbon present. More the percentage of carbon in steel more there is formation of marten site.

By hardening the steel, it becomes capable to cut other metals but at the same time as the harness of the steel increases the brittleness also increases accordingly.

TEMPERING

Hardened metal is not directly used due to risk of cracking. It is tempered to remove the internal stresses of the metal. It is a process of heating the hardened metal upto small temperature and then cooling it by quenching in oil.

CASE HARDENING

It is the process in which the upper layer of the work piece is hardened and the central part remains ductile core with hard upper surface.

NORMALIZING

It is also used for refining the steel structure. Here the steel is heated above the critical point and then it is cooled in air. It removes the internal stresses and increases the toughness. In this way the steel becomes suitable for commercial purposes.

PRECAUTIONS IN FORGING SHOP

1. The fire should be lightened in the hearth very carefully.2. There should be no leakage of fuel from pipes and pipe joint.

3. All the exhaust gases and smoke should go to the chimney.

4. The metal piece should neither be over heated nor under heated.

5. Do not touch any metal part unless you know that its temperature is normal.

6. Heavy blows of hammer should only be given by keeping the work piece in the centre on the anvil.

7. Never handle the tongs and hammer loose while working.

8. Never wear silky cloths in forging shop while working.

Brilliant blog about the basics of Forging and it’s processes.Pictorial representations of various types Forging processes along with up-to-date information and relevant content makes it easy to understand the difficult Forging processes. Thank you for posting this excellent blog.

ReplyDeleteVery nice post, impressive. its quite different from other posts. Thanks for sharingMachined components | Forging machine

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteIt's bad information

ReplyDeleteGreat blog posted here. keep posting.

ReplyDeleteyou can buy welding torches in ludhiana here.